Fascinating shapes, produced down to the gram: Furniture, lights, home accessories and even complete interiors can be created using 3D printing. This innovative technology seems to be pushing the boundaries of what is possible. Is additive manufacturing the future of interior design? Here are five good arguments in favour.

In 3D printing, individual layers of a material are applied one after the other and joined together. In the 1980s used primarily for the production of prototypes, this highly developed technology is now developing its strengths in more and more areas of application.

1. Beautifully shaped circular economy

Actually, 3D printing solves one of the biggest problems of the circular economy: the purity of the materials to be recycled. To build on this advantage, players around the world are working on optimising raw materials and processes. One start-up that is currently making a name for itself in this area is the Ambiente exhibitor Recozy. Its holistic approach includes a take-back system that allows customers to feed their Recozy items back into the material cycle. “Our concept is particularly popular with corporate customers, who can use it to make regular updates to their interior design in the office or at the point of sale circular”, reports Finn Hillen, co-founder of Recozy.

2. High scalability

The fact that 3D printing is certainly not a niche technology is demonstrated by as market leader renowned company Signify with its collections that are aligned to the circular economy. The lights in the “Grand” family, for example, are printed directly to order in the Belgian factory. Customers can choose from different colours, shapes and textures.

3. Exclusivity on demand

At the same time, the ability to produce on demand reduces logistics and storage costs – and contributes to the megatrend of individualisation. In particular, young designers are taking advantage of these benefits, as the Ambiente support programme “Talents” shows. In 2019, for example, the UAUproject from Warsaw presented colourful home accessories that it prints on request. Babette Wiezorek, a 2020 Talents participant, explores the creative possibilities of ceramic materials in her Berlin studio Additive Addicted. Impressive results include the “Supersonic”, “Breeze” and “Deep Blue” series.

4. Creative freedom

The ability to produce complex shapes, some of which would be impossible to realise using conventional manufacturing methods, makes additive processes particularly attractive for creative designers. Belgian Peter Donders, for example, had the 3D-printed sand mould for his famous “Batoidea” chair produced using the same technology that is used for the inner core of the Ferrari engine.

5. Efficient design process

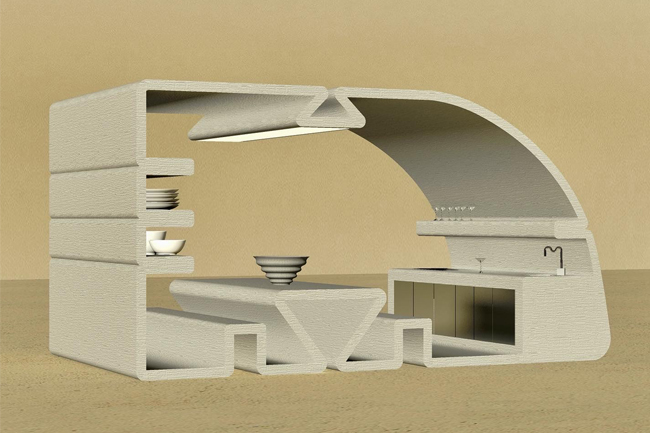

Last but not least, technological innovations are ensuring that additive processes are revolutionising the design process more than ever before. Whether artificial intelligence, new materials or processes: Models, prototypes and products can be created ever faster and more cost-effectively. French studio Argot demonstrates the creative potential of this in fascinating studies, including five complete rooms – printed from concrete (see image above).

Header image: Additive Addicted